I have always enjoyed working with computers ever since tooling around as a kid with my TRS-80 Color Computer and phoning up other computers (known as BBS’s for Bulletin Board Systems – pre-internet) on my 300 baud Hayes smartmodem. Everyone knows about how long it takes for an internet page to load these days. Imagine watching the page load line by line as each line slowly scrolls across the screen. That is the lightening speed we were used to back in the early ‘80s. Then someone got the bright idea (don’t believe Mr. Gore!) that it would be beneficial to connect all these computers together that were hosting the various sites and thus the internet was born.

Anyway, I have continued my interest in computers as a kid and have since enjoyed a career as a systems administrator. Most of what I know has been gathered thru past knowledge, schooling, and on the job experience at my first IT gig for an HP reseller in Austin . Then came the opportunity of a lifetime…I got a call in early 2004 from my uncle who was starting up another exploration company and needed someone to setup and administer the IT side of it. Not only would I be able to create the network from scratch but I would have an opportunity to learn many new things associated with the oil and gas industry of which I knew little to nothing about. Knowing my uncle’s successful track record and knowing that he would be a wonderful teacher from whom to learn the aspects of the industry, I felt it was a no brainer. What I failed to realize was how MUCH I would learn and what type of learning opportunities would arise. I thought I would share one of these recent experiences here…

Anyway, I have continued my interest in computers as a kid and have since enjoyed a career as a systems administrator. Most of what I know has been gathered thru past knowledge, schooling, and on the job experience at my first IT gig for an HP reseller in Austin . Then came the opportunity of a lifetime…I got a call in early 2004 from my uncle who was starting up another exploration company and needed someone to setup and administer the IT side of it. Not only would I be able to create the network from scratch but I would have an opportunity to learn many new things associated with the oil and gas industry of which I knew little to nothing about. Knowing my uncle’s successful track record and knowing that he would be a wonderful teacher from whom to learn the aspects of the industry, I felt it was a no brainer. What I failed to realize was how MUCH I would learn and what type of learning opportunities would arise. I thought I would share one of these recent experiences here… Obviously, we drill wells looking for oil & gas (mainly gas). Being the extremely wonderful teacher that he is, my uncle has patiently undertaken the painstaking task of explaining the ins and outs of the business that he has been so successful at for the past 30 years to a layman such as myself just so that I can have a better understanding of the industry for which I am now a part of. After many insightful meetings and many answered questions, it was time to take an overnight field trip – to the drilling rig!

Obviously, we drill wells looking for oil & gas (mainly gas). Being the extremely wonderful teacher that he is, my uncle has patiently undertaken the painstaking task of explaining the ins and outs of the business that he has been so successful at for the past 30 years to a layman such as myself just so that I can have a better understanding of the industry for which I am now a part of. After many insightful meetings and many answered questions, it was time to take an overnight field trip – to the drilling rig! We drove to Freeport , Tx (about an hour south of Houston ) where we hopped on the 135 foot crew boat that would take us the short 7 miles offshore to the Todco rig. The seas were calm and the day was nice so the boat ride was pretty smooth much to the disappointment of some of the veterans who wanted us to experience an icy wind with rough seas so we would really know what it could be like when you have to say hello to Captain Ralph. Fortunately for those of us on this excursion, that was not the case.

We drove to Freeport , Tx (about an hour south of Houston ) where we hopped on the 135 foot crew boat that would take us the short 7 miles offshore to the Todco rig. The seas were calm and the day was nice so the boat ride was pretty smooth much to the disappointment of some of the veterans who wanted us to experience an icy wind with rough seas so we would really know what it could be like when you have to say hello to Captain Ralph. Fortunately for those of us on this excursion, that was not the case. The first thing I noticed upon our arrival at the rig was the absence of an elevator or stairs. How the hell would we get up the 100+ feet to the rig floor? That’s when I saw the crane begin to move the net basket our way. I hadn’t realized I had signed up for Coast Guard training! We put our bags in the middle of the basket and no sooner had the last person stepped onto the thing did it start to carry us away from the boat. I figured there would be someone to give the crane operator a hand signal or something that we were ready. I was wrong so I held on for dear life. I certainly didn’t want to have my name mentioned in the daily rig reports under “accidents” that are emailed to everyone at our company, much less the Houston Chronicle obituaries.

The first thing I noticed upon our arrival at the rig was the absence of an elevator or stairs. How the hell would we get up the 100+ feet to the rig floor? That’s when I saw the crane begin to move the net basket our way. I hadn’t realized I had signed up for Coast Guard training! We put our bags in the middle of the basket and no sooner had the last person stepped onto the thing did it start to carry us away from the boat. I figured there would be someone to give the crane operator a hand signal or something that we were ready. I was wrong so I held on for dear life. I certainly didn’t want to have my name mentioned in the daily rig reports under “accidents” that are emailed to everyone at our company, much less the Houston Chronicle obituaries. You could obviously tell this was an older drilling rig, although it was still quite impressive. It was like night and day compared to the land rig my uncle had previously taken us to and there was much to see with a lot more activity. The first person we met was the “Company Man”. This is the person who is in charge of representing our company’s presence and interest on the rig. He was going to give us a tour but since our arrival coincided with one of four meals served throughout a 24 hour period, it was time to eat lunch. It was 10:30am and I am on a drilling rig offshore in the Gulf of Mexico and the first words I hear are, “Getcha a plate and grab yer a steak!” I walk out the backdoor of the kitchen and the chef is working the outdoor BBQ pit and proceeds to throw a huge ribeye on my plate cooked to my specifications. Only in Texas !

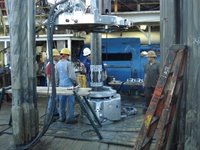

You could obviously tell this was an older drilling rig, although it was still quite impressive. It was like night and day compared to the land rig my uncle had previously taken us to and there was much to see with a lot more activity. The first person we met was the “Company Man”. This is the person who is in charge of representing our company’s presence and interest on the rig. He was going to give us a tour but since our arrival coincided with one of four meals served throughout a 24 hour period, it was time to eat lunch. It was 10:30am and I am on a drilling rig offshore in the Gulf of Mexico and the first words I hear are, “Getcha a plate and grab yer a steak!” I walk out the backdoor of the kitchen and the chef is working the outdoor BBQ pit and proceeds to throw a huge ribeye on my plate cooked to my specifications. Only in Texas ! Now it was time for my nap….uhh…..I mean tour. The rig may not be much to look at but as you walk around and see the inner workings and begin to understand how each part of the drilling rig has a function and you see how all these functions work together, it gets to be quite extraordinary. The heart of the operation occurs on the drilling floor, where all the actual drilling takes place. From this elevated platform you can see most of the activity of the rig, including an up close and personal view of the drill pipe going down the hole. As the driller works the machine that places the drill pipe in the hole, the roughnecks connect the sections of pipe as the hole gets drilled deeper. Each section of pipe is 30 feet and they add 3 pipes (90 feet) at a time to the hole. This particular well is going to be drilled to a TVD (total vertical depth) of approx 8000 feet. Because this is being drilled as a deviated hole, the actual or measured depth is considerably larger than that, thus you can imagine the amount of drill pipe needed.

Now it was time for my nap….uhh…..I mean tour. The rig may not be much to look at but as you walk around and see the inner workings and begin to understand how each part of the drilling rig has a function and you see how all these functions work together, it gets to be quite extraordinary. The heart of the operation occurs on the drilling floor, where all the actual drilling takes place. From this elevated platform you can see most of the activity of the rig, including an up close and personal view of the drill pipe going down the hole. As the driller works the machine that places the drill pipe in the hole, the roughnecks connect the sections of pipe as the hole gets drilled deeper. Each section of pipe is 30 feet and they add 3 pipes (90 feet) at a time to the hole. This particular well is going to be drilled to a TVD (total vertical depth) of approx 8000 feet. Because this is being drilled as a deviated hole, the actual or measured depth is considerably larger than that, thus you can imagine the amount of drill pipe needed. After a lobster dinner (haha – actually pork chops and pasta), we watched from the drilling floor as they made what is called a “short trip”. This is a term used to describe what happens when a portion of the drill pipe is pulled out of the hole for testing purposes and then put back in. Once the drill pipe was back in the hole, they ran a couple of circulations of mud thru it to flush out the cuttings from the wellbore. Once this is done they were going to do a full trip (pull out all of the drill pipe) so that they could run casing and cement thru the top 3800 feet of the well. We decided it would be a good time to catch some shuteye while they did the full trip so we could watch them case the well in the morning.

After a lobster dinner (haha – actually pork chops and pasta), we watched from the drilling floor as they made what is called a “short trip”. This is a term used to describe what happens when a portion of the drill pipe is pulled out of the hole for testing purposes and then put back in. Once the drill pipe was back in the hole, they ran a couple of circulations of mud thru it to flush out the cuttings from the wellbore. Once this is done they were going to do a full trip (pull out all of the drill pipe) so that they could run casing and cement thru the top 3800 feet of the well. We decided it would be a good time to catch some shuteye while they did the full trip so we could watch them case the well in the morning. The sleeping arrangements on this particular rig were quite sufficient and not as bad as you might think. We were in a room with 1 bunk bed and another single bunk. Each living quarters housed either 3 or 4 people. I imagine these beds felt like heaven to a lot of these guys when they get done with their daily duties. I have worked 12 hour shifts and I know how tiring they can be, let alone all the physical labor these workers go thru in a day. Although the sleeping quarters were adequate, the bathrooms were similar to those one might find down at the county lock up. If you could flush the toilet with your foot, you were good to go!

The sleeping arrangements on this particular rig were quite sufficient and not as bad as you might think. We were in a room with 1 bunk bed and another single bunk. Each living quarters housed either 3 or 4 people. I imagine these beds felt like heaven to a lot of these guys when they get done with their daily duties. I have worked 12 hour shifts and I know how tiring they can be, let alone all the physical labor these workers go thru in a day. Although the sleeping quarters were adequate, the bathrooms were similar to those one might find down at the county lock up. If you could flush the toilet with your foot, you were good to go! After breakfast we watched them lay the casing in the hole and that took them the better part of half a day. Their next step would be to cement the casing, let it dry, run a good circulation thru the hole and then it would be time to put the drill pipe back in the hole and continue drilling. Barring any setbacks, the whole drilling process generally takes around 18 days. Not long after they finished casing the hole, the crew boat was ready to take us back to Freeport so we had one last ride in the basket. This time I was a pro and I had the look of a true roughneck as I rode one handed down to the boat….piece of cake! One thing that troubled me however were the life jackets they give you for your journey on the basket. They are about the size of a breath mint so I don’t particularly know what good they would be other than the fact that they are bright orange, thus making them easily visible for the divers while you are laying on the sea floor.

After breakfast we watched them lay the casing in the hole and that took them the better part of half a day. Their next step would be to cement the casing, let it dry, run a good circulation thru the hole and then it would be time to put the drill pipe back in the hole and continue drilling. Barring any setbacks, the whole drilling process generally takes around 18 days. Not long after they finished casing the hole, the crew boat was ready to take us back to Freeport so we had one last ride in the basket. This time I was a pro and I had the look of a true roughneck as I rode one handed down to the boat….piece of cake! One thing that troubled me however were the life jackets they give you for your journey on the basket. They are about the size of a breath mint so I don’t particularly know what good they would be other than the fact that they are bright orange, thus making them easily visible for the divers while you are laying on the sea floor.All in all the experience was one I will never forget. Many props go out to all those guys who work tirelessly and efficiently together on those rigs. Those guys definitely earn every dime they get. I also cannot thank my uncle enough for taking the time to show and teach us the workings of the industry from inside and out. It is truly obvious that he loves what he does and the work environment that he creates makes this feeling very contagious.